Choose the correct mechanical gloves for your employees to work with, EN388:2003 vs EN388:2016

Due to anecdotal evidence, many employers continue to wrongly refer to the proper glove type inside their safe work systems. As a result, we've chosen to provide you with a bit more information on the differences between the two variants of the mechanical glove standard EN388 to give you a better understanding of how to choose the correct form of hand protection for your employees.

To keep up with the continually changing work settings, the testing standards for safety gloves were upgraded in 2016. According to the National Safety Council, cut-related occurrences, which include scratches, puncture wounds, severe lacerations, and abrasions, account for 30% of occupational injuries, with around 70% of these accidents involving the hands and fingers. As a result, the 2016 testing standards were well received. The EN 388:2016 standard now encourages brand manufacturers to fully support the manufacture and maintenance of hand protection products that adhere to workplace safety norms and help to establish an enduring safety culture even in regions where accidents are common.

It is important for employers to gain a better understanding of EN 388, how it has changed through the years, and more importantly, its significant impact on the life and safety of every worker.

What is the EN 388 standard?

EN 388 is a European standard that is used to monitor and evaluate the performance of safety gloves against mechanical risks. This is accomplished by assessing the fabric's or layers' ability to withstand heavy cutting by sharp objects, rubbing, ripping, and puncture. It is related to the ANSI/ISEA 105 standard, which is used in North America. Every glove product must pass stringent tests and be graded for abrasion, cut, tear, and puncture resistance.

Due to the general retained manual dexterity, mechanical EN 388 gloves are a popular choice among workers. However, this can be an Achilles heel because a lack of impact protection does little to reduce the severity of sustained hand and finger injuries.

What’s changed?

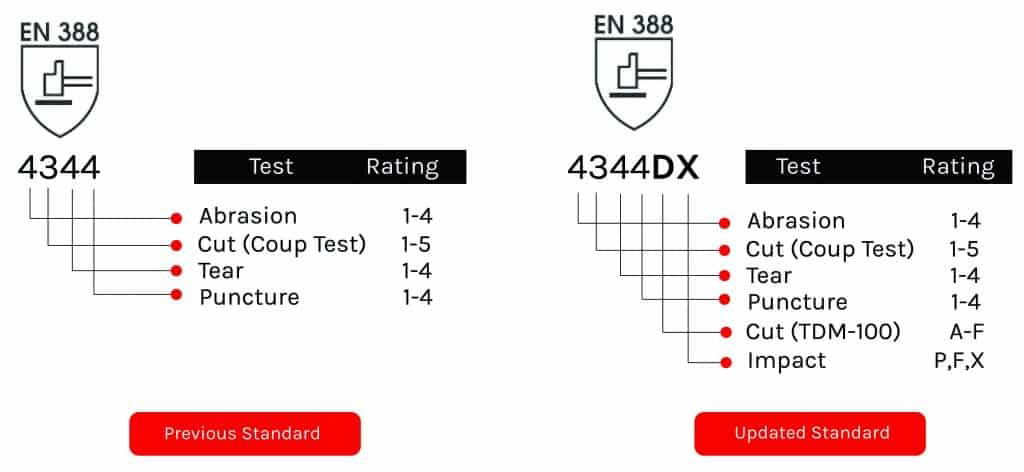

The first cut test standard, EN 388:2003, was developed in 2003. The previous version addressed the test criteria for protecting users from mechanical hazards. It applies to all sorts of safety gloves to protect against physical and mechanical aggressions caused by blade cuts, puncture, tearing, and abrasion.

The standard was amended on November 4, 2016, and is currently implemented as EN 388:2016. It still covers the same test standards to defend against mechanical threats, but it now additionally incorporates Straight Blade or Cut (TDM-100 Test) and Impact testing.

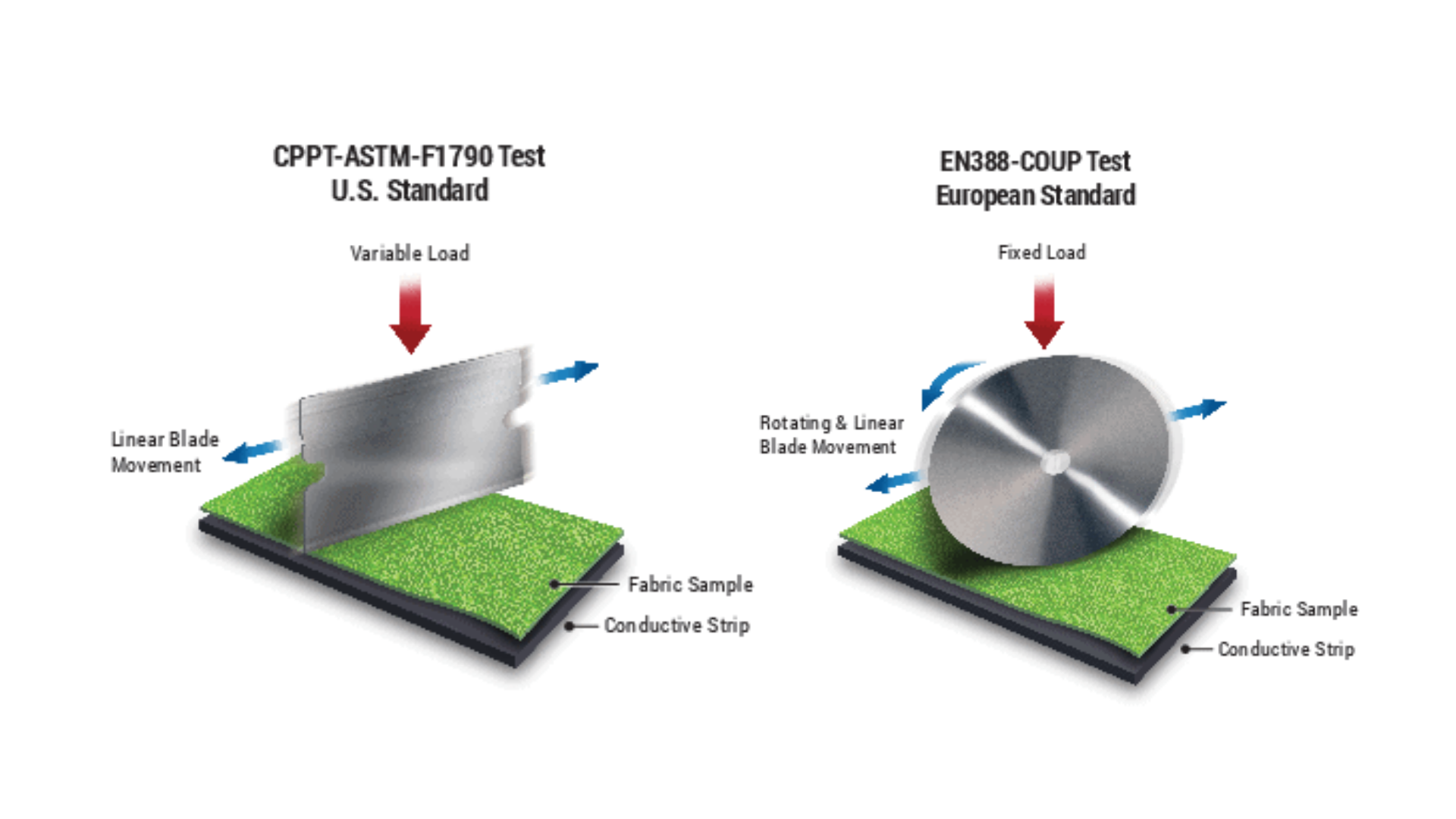

The Cut TDM-100 Test, or ISO 13997, is legally included in EN 388:2016. The TDM machine with sliding blade and weights is used in this test (see below)

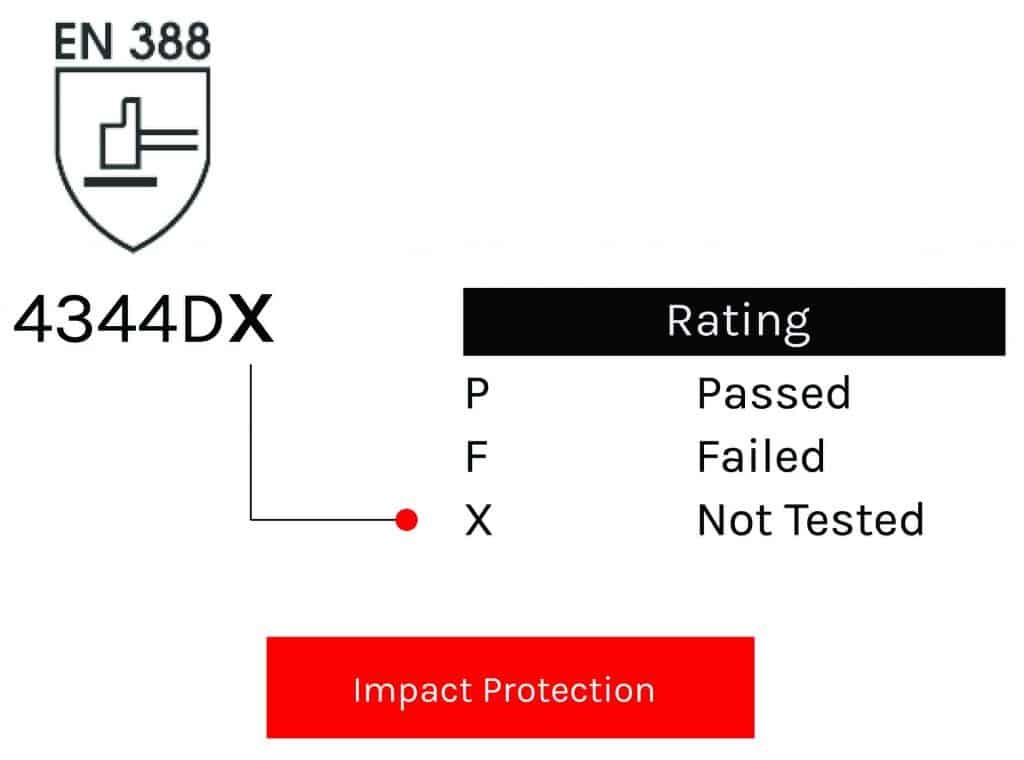

One of the key elements of the new standard is the inclusion of an impact protection test. All safety gloves are tested to determine their impact resistance. The impact protection test uses the following ratings: Passed (P); Failed (F); and Not Tested (X). See figure below.

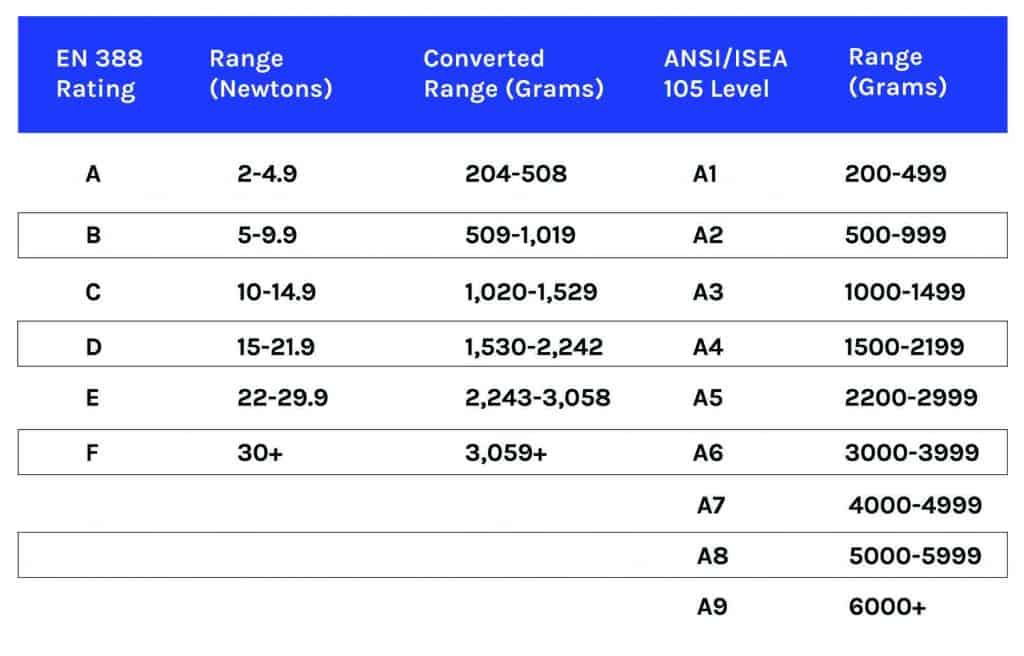

From Newton to Gram scoring

The new EN 388 2016 standard is now aligned with its US counterpart – the ANSI/ISEA 105 standard for cut resistance when converting Newtons to Grams. See table.

Why is it critical?

Many gloves are still labelled EN 388:2003 and are still good to use. Those labelled according to the EN 388:2016 standard, on the other hand, offer greater protection, which could mean increased safety and comfort over its predecessor. Safety personnel should never take this for granted. In general, if the glove product meets the requirements of the EN 388 2016 standards, it can be exported commercially and utilised extensively in a variety of industries where significant cuts are most likely to occur.Businesses will gain from this because it not only protects one of the body's vital organs but also drives operational efficiency and performance. It is worth noting that the performance of safety gloves has never changed. It is the manner in which their performance is tested that changes!

Are you looking for cut-resistant gloves that adhere to the right industry standards?

We highly recommend Casswells Group for expert assistance and unrivalled interpersonal service when it comes to workplace safety equipment. They provide an extensive range of industry standard safety gloves appropriate across a variety of sectors. You can view their range here https://www.caswellsgroup.com/Personal-Protection-Equipment/Hand-Protection?s=gloves